SERVICES

Recovering Value for the Earth

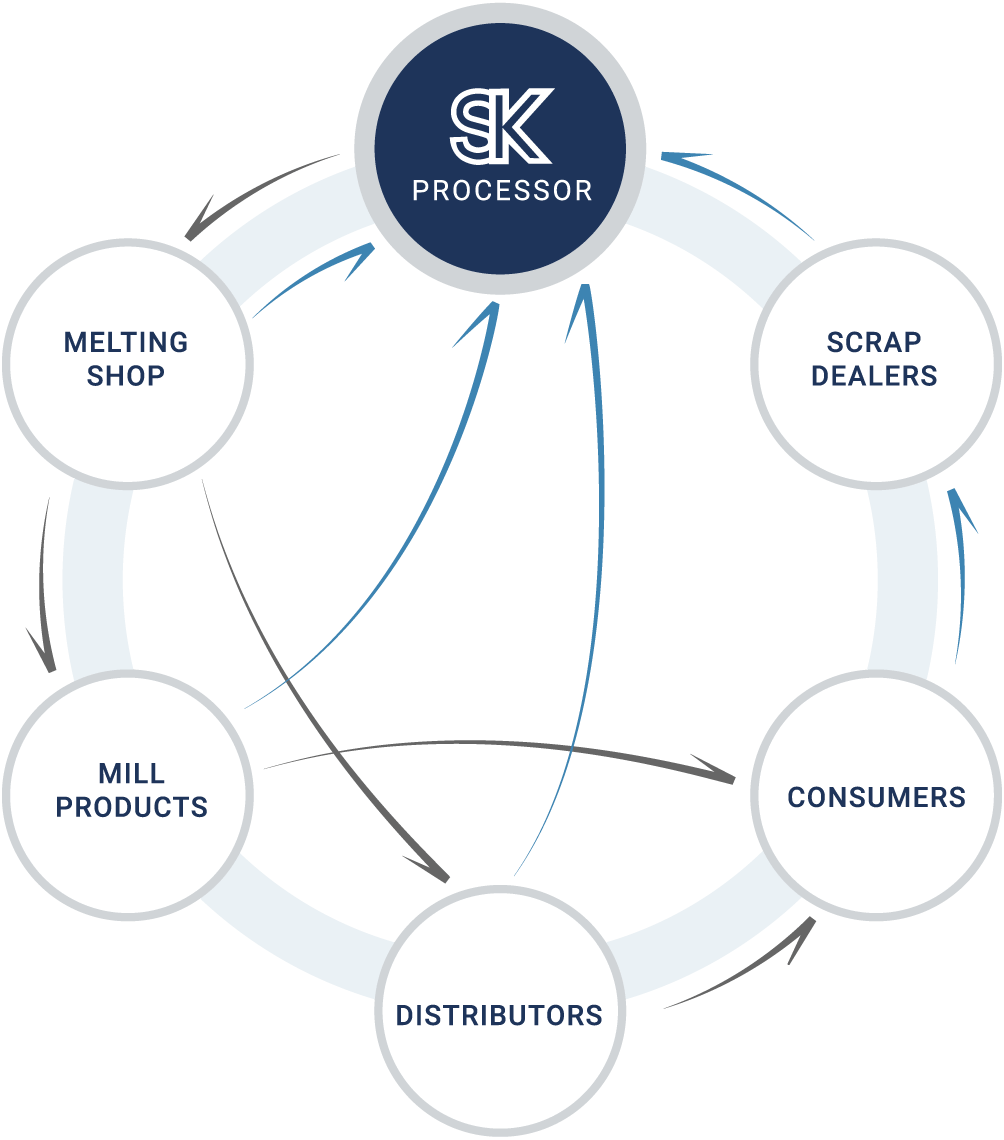

Since its founding, Showa Metal has grown through the rigorous rare metal scrap sorting and processing skills it has developed and the collection and sales network it has built around the global scrap industry market. Both advantages allow us to offer reliable value to our customers and to contribute to global environmental preservation through the recycling of resources.

We are proud of being a “processor” that breathes life back into rare metal scrap, helping to reinvigorate the quality of the earth.

VALUE CREATION PROCESS

Related Industries

-

AEROSPACE

High-performance alloys that satisfy light weight, high strength, high toughness and heat resistance are often used in the aerospace industry. The raw material required must meet strictly controlled quality standards.

-

POWER PLANTS

High-temperature strength and high corrosion resistance are required for long-lasting durability even in harsh environments, and these specialty alloys comprise various sections of thermal and nuclear power plants.

-

PETROCHEMICAL PLANTS

High-performance alloys with strong corrosion resistance that can withstand corrosion due to various chemical substances and harsh environments are used.

-

SHIPBUILDING

Alloys that display strong corrosion resistance even when kept immersed in sea water and that also feature different properties such as wear resistance and high temperature resistance are used.

-

AUTOMOBILES

In order to respond to environmental regulations that have become increasin gly strict, many different kinds of special alloy castings have been developed to improve the efficiency of internal combustion engines and to reduce the weight of exhaust system parts that are required to have high heat resistance.

“On-site Mobility”-

adding value to scraps

Our Kawasaki Head Plant is collecting special alloys and rare metal scraps from domestic and overseas markets for special steel and super alloy producers, carrying out sorting and processing and executing quality checking, packing and shipping.

We have an environment where

teams can operate

flexibly

in order to suit every application.

The strength of the Kawasaki Head Plant is its ability to deal with any type of scrap, such as powder form scrap and scrap requiring dismantlement, irrespective of shape and size.

In addition, it has the flexibility to cope with any type of steel alloy. The quality level required by customers varies, depending on the purpose, but the plant can respond exactly to any of those needs. The location, which is easily accessible from major ports around Tokyo, Yokohama and the Tokyo Metropolitan Expressway in the bayside area, is perfect for scrap-handling operations and improves access to these services.

FOR QUALITY

-

01Receiving

-

02Scale

-

03Radioactivity

Inspection -

04Analysis

Inspection -

05Cutting

Repacking -

06Shipping

Our advanced capabilities

guarantee the quality of scrap

Titanium has a light specific gravity, high strength and high corrosion resistance that is better than any other major metal, and it is known as an excellent material found in various environments throughout the ocean and the earth. The Naoetsu Plant specializes in titanium scrap recycling and is proud of its unparalleled processing facility and the volume it is handling not only in Japan but throughout Asia.

The reason for our consistent high level of quality is

outstanding technical strength and strict quality control standards.

Titanium ingots, the source of titanium products, are melted in a vacuum furnace, and the scrap as raw material for titanium ingot manufacture must meet the quality standards for vacuum melting. The Naoetsu Plant features the advantages of advanced sorting skills and strict quality control. That is the source of its competitiveness.

FOR QUALITY

-

01Receiving

-

02Scale

-

03Radioactivity

Inspection -

04Analysis

Inspection -

05Processing

Cutting

Shot-Blasted

Washing

Blending -

06Weighing

Packing -

07Shipping

Advanced technology that

helps in realizing a sustainable value cycle for resources

Industries like aerospace and power generation require adherence to strict product standards. This is particularly crucial for scrap materials used in aircraft engines, where the highest quality is necessary. Drawing on the expertise and high-quality standards we have cultivated over many years in working with titanium raw materials, we established a dedicated nickel alloy scrap recycling facility at our Naoetsu plant.

Enhanced competitiveness through advanced recycling technology

At our new Naoetsu plant, we are embracing the challenge of raw material recycling to meet the growing demand for carbon neutrality in today's society. In addition to our proven track record with titanium, we are now recycling scrap produced during the manufacturing processes of specialty steel manufacturers. In doing so, we establish closed-loop raw material cycles with various manufacturers, reinforcing our role as a key scrap processor within the resource value cycle. We strive to achieve advanced recycling and enhance our competitive edge by leveraging the crushing, washing, and quality control techniques we have honed through working with titanium raw materials.

FOR QUALITY

-

01Receiving

-

02Scaling

-

03Radioactivity

inspection -

04Analysis

Inspection -

05Processing

Cutting

Washing -

06Weighing

Packing -

07Shipping